Key Takeaways:

- The Korth semi-automatic pistol was never a compromise design: From its materials to its locking system, the pistol reflects the same obsessive standards that defined Korth revolvers. It was engineered without regard for production efficiency, cost reduction, or institutional convenience, only mechanical integrity and longevity.

- Prototype No. 005 represents a complete, functional endpoint, not an experiment: Despite its prototype status, No. 005 underwent extensive testing, demonstrated exceptional durability, and showed virtually no measurable wear even after heavy use. Its performance suggests the design had already matured, even if broader adoption never followed.

- The pistol’s rarity is the result of philosophy, not failure: Delayed timelines, limited numbers, and eventual withdrawal from formal programs were outcomes of Korth’s refusal to dilute standards. In hindsight, this places the early Korth semi-automatic pistols in a narrow historical category: technically successful, commercially indifferent, and historically irreplaceable.

Let’s get started…

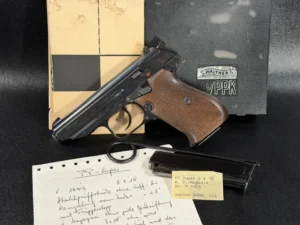

So there’s this pistol. Prototype No. 005. And honestly, if you’re into firearms history or just appreciate things built to absurd levels of quality, this thing is kind of fascinating.

Willi Korth showed it off at the IWA exhibition in Nuremberg back in 1982. People noticed. But here’s the weird part: nothing really happened for years. The first actual production pistols didn’t ship until 1989, and by then, it wasn’t even Korth’s company anymore. The successor firm delivered them. Seven years from debut to delivery. That’s… not how you launch a product.

But let’s back up.

The groundwork for this pistol goes back to the mid-70s. Korth had already machined the steel components for prototypes and worked out the mechanical guts of the design. He wanted to submit it for consideration in some German police and military pistol program. Makes sense, right? Except he missed the deadline. The first working prototype just wasn’t ready in time. And that pretty much set the tone for everything that followed.

What Made It Different

The gun itself was a double-action/single-action semi-auto. Nothing crazy there. But the locking system? That’s where Korth went his own way. Most pistols at the time used a tilting-barrel setup. Standard stuff. Korth said no thanks and built a rigid barrel with this swinging locking-lug mechanism instead.

He was obsessed with keeping things mechanically simple. The trigger system, minus the springs, used just a handful of moving parts. You know how some designs pile on components until you’re basically looking at a watchmaker’s nightmare? Not this. Korth stripped it down to what actually needed to be there.

And then there’s the materials. If you know anything about Korth revolvers, you know the guy didn’t mess around. High-grade steels throughout. Surface-hardening treatments on critical parts that resulted in durability you could probably measure in geological time. Seriously, the tensile strength and surface hardness of these components were borderline excessive. But that was kind of the point.

The barrel assembly is where it gets interesting. Korth made these from specialized steel blanks using forging or cold-hammering. The result was this incredibly dense, polished chamber surface. And here’s a neat detail: instead of using a sharply defined transition cone like most pistols, Korth guided the projectile directly into the rifling lands. Less gas loss at ignition. The barrel blank was about 260mm long, roughly 23mm in diameter. Not massive, but built like a vault.

The Early Prototypes

Prototypes 003, 004, and 005 were among the first completed examples. They got photographed in early 1982, probably for exhibition materials and documentation. Prototype 005 was the first to be truly finished, and it became the reference model for everything that came after.

It was chambered in 9x19mm Parabellum. Combat-oriented setup with a 10-round magazine. There were two barrel configurations floating around: standard length and an extended version that came later. Funny enough, the extended barrel was originally meant for a different prototype and wasn’t even finished when it showed up.

The sights are worth mentioning. On the standard setup, the front sight was machined right into the barrel sleeve. One piece. The extended barrel used a separate front sight attachment at the muzzle instead. The rear sight sat in the slide, held by a spring-loaded retention system. You could adjust it laterally, but not vertically. No elevation adjustment on the combat model.

This sight arrangement only appeared on a few early prototypes. It didn’t carry over to later production guns. Korth filed a patent application in early 1982 covering parts of the sighting and locking system. It got published in 1983. Then he withdrew it. Make of that what you will.

Markings and Details

The manufacturer’s markings were etched on the left side of the slide. If you’re used to seeing Korth revolvers with their round emblem, the pistol version had a flattened profile instead. Full company name spelled out next to the symbol, followed by the caliber designation. The engraving quality on early examples is… let’s say inconsistent. You can see minor variations. But these were prototypes. That kind of comes with the territory.

Grip panels were oiled walnut with fine texturing cut into them. There was also a separate walnut palm swell inset at the rear of the grip frame. Nice touch for control and feel. Serial numbers went on the right side of the frame near the trigger guard. Consistent format across the earliest prototypes.

Testing It

Here’s where it gets impressive.

Prototype 005 went through extensive firing and endurance testing. And when I say extensive, I mean they put ridiculous round counts through this thing over short testing periods. Contemporary accounts suggest they were really trying to break it.

They couldn’t.

Wear was minimal. There was some light burnishing on the grip frame where the hands repeatedly made contact. Under magnification, you could see slight polishing on the locking surfaces. That’s it. The barrel? Effectively, no wear. No measurable loss of accuracy or reliability. Even after all that abuse, the lockup was tight with virtually no detectable play.

Based on these results, people began discussing service life expectations in the six-figure range. As in, over 100,000 rounds. Maybe way over. The design just didn’t quit.

Functionally, it fed reliably from full magazines, including those tricky first few cartridges that give many pistols fits. They needed to make minor sight adjustments because of height differences between sport and combat configurations, but that’s not exactly a fundamental flaw.

What Happened Next

Prototype 005 became the poster child for Korth pistols in publications. For years. Even in reference works published well after the prototype era, it kept showing up as the example of Korth’s semi-auto development.

That extended barrel I mentioned earlier? It eventually surfaced among components from Willi Korth’s estate. Even though it was originally meant for a different pistol, the owner fitted and finished it anyway.

Why It Matters

Look, the Korth semi-automatic never came close to matching the commercial success of Korth’s revolvers. Not even in the same ballpark. But Prototype No. 005 remains important because it embodies Willi Korth’s design philosophy at its most uncompromising.

This wasn’t designed to be a mass-produced service sidearm. It wasn’t cost-driven. It was a technical exercise. Durability, precision, and mechanical restraint were pushed to their limits. That was the goal.

The delayed production, the limited numbers, the prototype-heavy development history… none of that reflects problems with the design itself. It was just too demanding. Too labor-intensive. Too indifferent to production economics to fit with what military and police procurement actually looked like in the late Cold War era. You want 50,000 units that meet spec and come in under budget? This wasn’t that gun.

The Bigger Picture

These early Korth semi-automatic prototypes, especially No. 005, occupy this weird niche in firearms history. They bridge the gap between Korth’s legendary revolver work and a semi-automatic line that never really got off the ground. Could have been something. Wasn’t.

As surviving artifacts, though, they’re revealing. They show an alternative path German precision gunmaking could have taken. One where longevity and mechanical integrity mattered more than everything else. Even when common sense suggested you should probably make some compromises.

In that sense, the Korth semi-automatic isn’t an unfinished project. It’s a complete statement. Quiet, exacting, and unmistakably Korth. A pistol that answered a question almost nobody was asking: what if you built something that simply refused to wear out, consequences be damned?

Funny enough, that might be exactly why it’s worth remembering.

Frequently Asked Questions

No. Although it was initially intended for consideration in German police and military service trials, the first fully functional prototype was not completed within the required submission window. As a result, the pistol was never formally evaluated or adopted by any service branch.

Only a small number of early prototypes are documented, with internal designations including 003, 004, and 005. Among these, Prototype No. 005 is the most complete and best documented example, serving as the reference model for later development.

Although the design and many precision-machined components were completed earlier, the transition from prototype to series production was delayed due to organizational changes and the transfer of responsibilities to a successor company. Series pistols were not delivered until 1989.

Unlike the tilting-barrel systems standard at the time, the Korth pistol used a rigid barrel combined with a swinging locking-lug mechanism. This approach prioritized consistency in lock-up and long-term mechanical stability rather than ease of manufacture.

Willi Korth approached the pistol with the same philosophy used in his revolvers: durability was non-negotiable. High-grade steels and surface-hardening treatments were selected to minimize wear, maintain tight tolerances, and extend service life well beyond conventional expectations.